Corepine smart tailgates ได้รับการออกแบบมาเพื่อเพิ่มประสิทธิภาพการทำงานของยานพาหนะทางการค้าของคุณ เหล่าประตูลากสินค้าอัจฉริยะเหล่านี้ช่วยให้การขนถ่ายสินค้ารวดเร็วและปลอดภัยมากขึ้น โดยลดเวลาหยุดทำงานลงอย่างเห็นได้ชัด ด้วยการเน้นที่คุณภาพและความทนทาน ประตูลากสินค้าอัจฉริยะของเราสนับสนุนการดำเนินงานโลจิสติกส์อย่างมีประสิทธิภาพ ช่วยให้ธุรกิจลดต้นทุนแรงงานและปรับปรุงการส่งมอบบริการ ไม่ว่าจะเป็นสินค้าขนาดเล็กหรือใหญ่ ประตูลากสินค้าของ Corepine มีโซลูชันที่หลากหลายและคุ้มค่า ซึ่งออกแบบมาเพื่อตอบสนองความต้องการเฉพาะของฝูงยานพาหนะของคุณ

Corepine Tailgate มีความเชี่ยวชาญในการร่วมมือกับ OEM โดยนำเสนอโซลูชันประตูท้ายอัจฉริยะที่ปรับแต่งได้อย่างเต็มรูปแบบ แก้ไขขนาดฮาร์ดแวร์ อินเทอร์เฟซซอฟต์แวร์ รวมถึงบรรจุภัณฑ์เพื่อให้ตรงกับแบรนด์ของคุณ ลูกค้า B2B ของเราได้รับประโยชน์จากทีม NPI เฉพาะและวงจรการผลิตที่เร่งรัด ด้วยประสบการณ์ OEM กว่า 15 ปี เราสามารถรับประกันการผสานรวมที่ราบรื่นเข้ากับกระบวนการผลิตของคุณ

Corepine ท้ายรถอัจฉริยะช่วยให้ธุรกิจลดต้นทุนแรงงานโดยการอัตโนมัติกระบวนการจัดการสินค้า เหล่านี้เป็นลิฟท์เกตขั้นสูงที่ออกแบบมาเพื่อทำให้การโหลดและการ缷สินค้าเร็วขึ้น ปลอดภัยขึ้น และมีประสิทธิภาพมากขึ้น โดยการลดความจำเป็นของแรงงานด้วยตนเอง ท้ายรถ Corepine ช่วยลดต้นทุนทางอ้อมและเพิ่มผลิตภาพในการดำเนินงาน ไม่ว่าคุณจะอยู่ในวงการโลจิสติกส์ การส่งของ หรือการขนส่ง ท้ายรถอัจฉริยะ Corepine เป็นทางออกที่คุ้มค่าเพื่อเพิ่มประสิทธิภาพการทำงานของฝูงยานพาหนะและปรับปรุงประสิทธิภาพโดยรวม

แก็ตวอทส์อัจฉริยะ Corepine คือตัวแทนของอนาคตในการจัดการสินค้าอย่างมีประสิทธิภาพ ลิฟท์เกตเหล่านี้ถูกออกแบบมาเพื่อปรับปรุงกระบวนการโหลดและ缷สินค้าสำหรับยานพาหนะเชิงพาณิชย์ ซึ่งช่วยเพิ่มผลผลิตและความปลอดภัยอย่างมาก โดยการอัตโนมัติในงานปฏิบัติการ แก็ตวอทส์อัจฉริยะของ Corepine ช่วยลดต้นทุนแรงงาน เพิ่มประสิทธิภาพการทำงาน และลดความเสี่ยงของการบาดเจ็บ ด้วยการผสานรวมที่ราบรื่นเข้ากับฝูงยานพาหนะของคุณ แก็ตวอทส์อัจฉริยะ Corepine มอบประสิทธิภาพและความน่าเชื่อถือระยะยาวสำหรับธุรกิจที่ต้องการปรับปรุงการดำเนินงานด้านโลจิสติกส์

ชุดท้ายรถอัจฉริยะของ Corepine Tailgate ผ่านการทดสอบความเครียดอย่างเข้มงวด รวมถึงการเปิด-ปิด 100,000 รอบและการสัมผัสกับสภาพอากาศสุดขั้ว สำหรับลูกค้า B2B นี่หมายถึงการบำรุงรักษาที่น้อยที่สุดและการประหยัดต้นทุนในระยะยาว ฟีเจอร์ด้านความปลอดภัย เช่น การหยุดฉุกเฉินและการตรวจจับน้ำหนักช่วยปกป้องผู้ใช้งาน ลดความเสี่ยงทางความรับผิดชอบ องค์กรผู้ดำเนินการยานพาหนะทั่วโลกให้ความไว้วางใจในระบบของเรา ซึ่งได้กำหนดมาตรฐานของอุตสาหกรรม

บริษัท Huizhou Yopine Technology Co., Ltd. ก่อตั้งขึ้นในปี 2550 ในเขตอุตสาหกรรมไฮเทคแห่งชาติจงไก มณฑลกวางตุ้ง ซึ่งตั้งอยู่ใกล้กับเซินเจิ้นและตงกวน โดยมีความเชี่ยวชาญในการพัฒนา ผลิต และจำหน่ายกลไกซีดี/ดีวีดีรถยนต์ ประตูท้ายไฟฟ้า และชิ้นส่วนรถยนต์ที่มีความแม่นยำ โดยมีพนักงานหลายร้อยคน ผลิตกลไกได้มากกว่า 5 ล้านชิ้นต่อปี บริษัทให้ความสำคัญกับนวัตกรรมเทคโนโลยีและมีประสบการณ์มากกว่าทศวรรษในการออกแบบ การผลิต และการจัดการคุณภาพรถยนต์ที่มีความแม่นยำ บริษัทจ้างบุคลากรที่มีทักษะและใช้เครื่องมือทดสอบขั้นสูง เช่น แท่นทดสอบการสั่นสะเทือน lMV ของญี่ปุ่น เครื่องวัด Mitutoyo และเครื่องทดสอบสิ่งแวดล้อมต่างๆ เพื่อให้แน่ใจว่าได้มาตรฐานคุณภาพสูง

ความสะดวกสบายแบบสัมผัสเดียวเพื่อการใช้งานจริงและความปลอดภัยของยานพาหนะที่ดีขึ้น

การตอบสนองอย่างรวดเร็วช่วยเพิ่มประสิทธิภาพด้านโลจิสติกส์และลดความเหนื่อยล้าในการปฏิบัติงาน

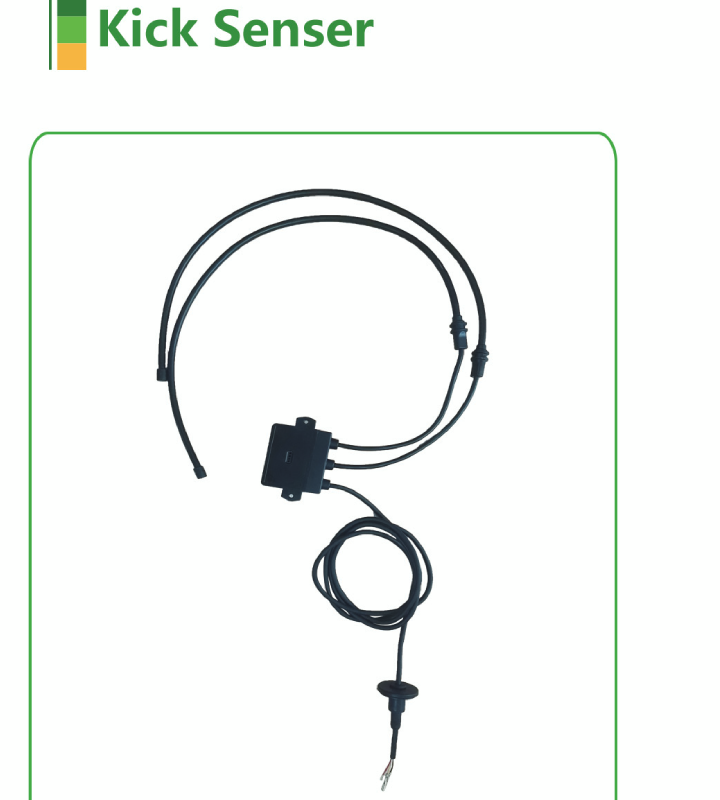

การตรวจจับอัจฉริยะทำให้การใช้งานในชีวิตประจำวันง่ายขึ้นด้วยการเปิดและปิดอัตโนมัติ

การควบคุมด้วยเสียงผสานเทคโนโลยีนวัตกรรมเพื่อประสบการณ์การขับขี่ที่ล้ำสมัย

ใช่ เราให้การเข้าถึง API และการปรับแต่งเฟิร์มแวร์เพื่อให้มั่นใจในความเข้ากันได้กับระบบจัดการยานพาหนะส่วนใหญ่

ประตูท้ายอัจฉริยะของเราปฏิบัติตามมาตรฐาน ISO 26262, E-MARK และ CE เพื่อให้มั่นใจในการเข้าถึงตลาดโลก

แน่นอน เราให้บริการบทแนะนำวิดีโอ การสัมมนาออนไลน์สด และการฝึกอบรมในสถานที่สำหรับพันธมิตร B2B

ระยะเวลาการผลิตขึ้นอยู่กับจำนวน แต่โดยทั่วไปแล้วจะอยู่ในช่วง 14 ถึง 30 วัน มีบริการการผลิตด่วนสำหรับคำสั่งซื้อด่วน

ใช่ เราเสนอหน่วยตัวอย่างในราคาที่ลดลงพร้อมกับการคืนเงินเต็มจำนวนเมื่อยืนยันการซื้อเป็นจำนวนมาก