Corepine excels in crafting bespoke auto tailgates for niche B2B applications. Whether you need temperature-controlled units, brand-specific interfaces, or integration with vehicle management systems, our engineering team delivers. Collaborate via our streamlined quotation system and enjoy transparent communication throughout production.

Reliability is essential when choosing auto parts for your business, and Corepine auto tailgates deliver just that. Engineered with precision and built to last, our tailgates ensure that your vehicles operate smoothly and efficiently. Corepine tailgates are designed to provide long-lasting performance, making them the perfect choice for businesses seeking reliable and durable automotive solutions.

Corepine’s auto tailgates integrate hydraulic dampers and anti-pinch sensors to reduce workplace injuries by 60%. For B2B clients, this means 50% faster loading cycles and 30% lower maintenance costs. Our tailgates use military-grade steel with a 500-hour salt spray resistance rating. With 150+ standard configurations, Corepine simplifies bulk procurement for global logistics firms.

Corepine provides a wide range of auto tailgate systems designed to meet the unique needs of every vehicle. With advanced engineering and high-quality materials, our tailgates provide superior performance and reliability. Whether you're looking to upgrade a single vehicle or supply a fleet, Corepine has the perfect auto tailgate solution to enhance your operations.

Corepine’s B2B portal offers real-time pricing, 3D product configurators, and AI-driven logistics optimization. For example, a Scandinavian client used our platform to reduce shipping costs by 25% by consolidating orders. Features like automated reorder alerts and digital documentation storage further simplify procurement.

Huizhou Yopine Technology Co., Ltd., established in 2007 in ZhongKai National Hi-tech Zone, Guangdong, strategically located near Shenzhen and Dongguan, specializes in developing, manufacturing, and selling car CD/DVD mechanisms, electric tailgates, and precision auto parts. With a workforce of hundreds, they produce over 5 million mechanisms annually. The company emphasizes technological innovation and has over a decade of experience in precision auto design, production, and quality management. They employ skilled personnel and utilize advanced testing equipment such as Japanese lMV vibration test benches, Mitutoyo measurers, and various environmental testers to ensure high-quality standards.

One-touch convenience for enhanced vehicle practicality and security.

Rapid response boosts logistics efficiency and reduces operational fatigue.

Intelligent sensing simplifies daily use with automatic opening and closing.

Voice control integrates innovative technology for a futuristic driving experience.

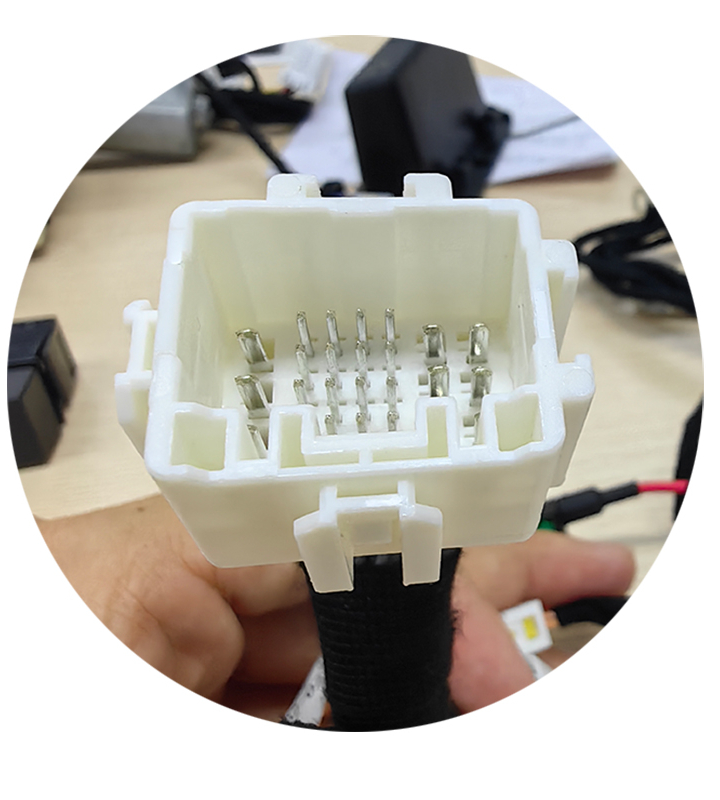

Yes, our tailgates support CAN bus and OBD-II integration for seamless compatibility.

Our MOQ starts at 20 units, with tiered pricing for larger orders. Contact our B2B team for a personalized quote.

Standard lead times are 18-28 days, depending on complexity. Expedited options are available for urgent requests.

Yes, our insulated and temperature-controlled models maintain -20°C to 20°C ranges.

All products include a 3-year warranty against manufacturing defects, extendable with service contracts.