Elevate your vehicle accessory offerings with Corepine Tailgate’s smart tailgate systems. Designed for B2B clients, our intelligent electric lifts feature hands-free operation, obstacle detection, and seamless OEM integration. Ideal for automotive distributors and manufacturers, these systems enhance safety and user convenience. With global certifications, bulk pricing, and dedicated account managers, Corepine Tailgate ensures your business delivers cutting-edge technology to end-users.

Corepine Tailgate offers end-to-end support for B2B growth. From flexible MOQs to localized marketing materials, we adapt to your market needs. Our global warehouse network enables just-in-time delivery, while our compliance team ensures adherence to regional regulations. Join 75+ partners who have expanded into new territories with Corepine Tailgate.

Maximize your fleet’s performance with Corepine’s innovative smart tailgates. These advanced liftgates are designed to improve the speed and safety of loading and unloading, ensuring a more efficient operation for your logistics team. Corepine tailgates are ideal for businesses looking to reduce manual labor, increase service delivery speed, and cut down on maintenance costs. With Corepine, you can achieve greater operational efficiency and reduce downtime, all while enhancing your fleet’s overall performance.

Automation is the future of cargo handling, and Corepine is leading the way with its smart tailgates. Designed to reduce the physical effort required for loading and unloading, these advanced liftgates ensure a smooth, fast, and safe operation. Corepine smart tailgates also reduce maintenance costs and downtime, making them a cost-effective solution for businesses looking to enhance their logistics operations. With Corepine, you can stay ahead of the competition by integrating the latest in automated cargo handling technology.

Investing in Corepine smart tailgates is a smart move for businesses looking to optimize their fleet management. These high-performance liftgates are designed to handle heavy loads efficiently, reducing the time spent on loading and unloading. Corepine tailgates offer durability and low maintenance, ensuring that your fleet operates smoothly over time. With smart technology that automates cargo handling, Corepine tailgates reduce labor costs and increase productivity, making them a valuable long-term asset for your business.

Huizhou Yopine Technology Co., Ltd., established in 2007 in ZhongKai National Hi-tech Zone, Guangdong, strategically located near Shenzhen and Dongguan, specializes in developing, manufacturing, and selling car CD/DVD mechanisms, electric tailgates, and precision auto parts. With a workforce of hundreds, they produce over 5 million mechanisms annually. The company emphasizes technological innovation and has over a decade of experience in precision auto design, production, and quality management. They employ skilled personnel and utilize advanced testing equipment such as Japanese lMV vibration test benches, Mitutoyo measurers, and various environmental testers to ensure high-quality standards.

One-touch convenience for enhanced vehicle practicality and security.

Rapid response boosts logistics efficiency and reduces operational fatigue.

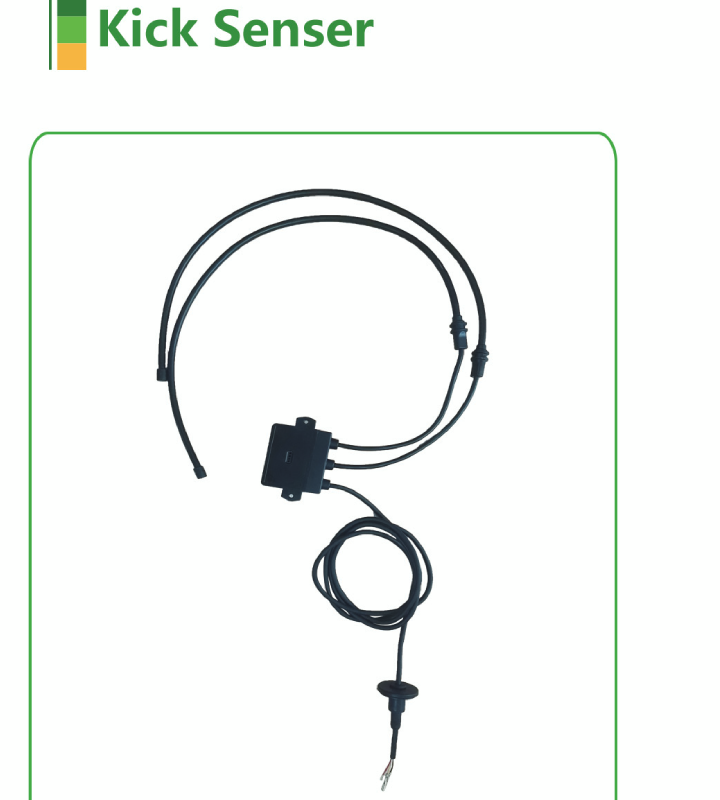

Intelligent sensing simplifies daily use with automatic opening and closing.

Voice control integrates innovative technology for a futuristic driving experience.

Yes, we provide API access and firmware customization to ensure compatibility with most vehicle management systems.

Our smart tailgates comply with ISO 26262, E-MARK, and CE standards, ensuring global market access.

Absolutely. We provide video tutorials, live webinars, and on-site training for B2B partners.

Lead times vary by quantity but typically range from 14 to 30 days. Express production is available for urgent orders.

Yes, we offer sample units at a reduced cost with a full refund upon bulk purchase confirmation.