As a leading manufacturer, Corepine Tailgate specializes in smart tailgate systems for B2B automation. Our solutions include app-controlled operation, voice activation, and adaptive learning for diverse vehicle types. For OEM projects, we offer co-development support and rapid prototyping. With 10+ patents in smart vehicle tech, Corepine Tailgate empowers businesses to lead in innovation.

Corepine smart tailgates help businesses reduce labor costs by automating the cargo handling process. These advanced liftgates are designed to make loading and unloading faster, safer, and more efficient. By reducing the need for manual labor, Corepine tailgates lower overhead costs and increase operational productivity. Whether you’re in logistics, delivery, or transportation, Corepine smart tailgates provide a cost-effective solution to streamline your fleet’s operations and improve overall efficiency.

Automation is the future of cargo handling, and Corepine is leading the way with its smart tailgates. Designed to reduce the physical effort required for loading and unloading, these advanced liftgates ensure a smooth, fast, and safe operation. Corepine smart tailgates also reduce maintenance costs and downtime, making them a cost-effective solution for businesses looking to enhance their logistics operations. With Corepine, you can stay ahead of the competition by integrating the latest in automated cargo handling technology.

Corepine smart tailgates offer numerous advantages for fleet operators. By automating cargo handling, these tailgates reduce the need for manual labor, cut down on injury risks, and speed up the entire loading and unloading process. Designed for heavy-duty use, Corepine tailgates are durable and easy to maintain, providing a reliable solution for businesses looking to improve their logistics operations. With Corepine, fleet operators can optimize their fleet’s performance, reduce costs, and enhance productivity.

Corepine Tailgate’s smart tailgate systems redefine vehicle automation for B2B buyers. By integrating AI sensors and IoT connectivity, our electric lifts enable hands-free operation and real-time diagnostics. For distributors, this means fewer service calls and higher customer retention. With 99.8% uptime in testing, our systems are engineered for reliability, backed by a global R&D network.

Huizhou Yopine Technology Co., Ltd., established in 2007 in ZhongKai National Hi-tech Zone, Guangdong, strategically located near Shenzhen and Dongguan, specializes in developing, manufacturing, and selling car CD/DVD mechanisms, electric tailgates, and precision auto parts. With a workforce of hundreds, they produce over 5 million mechanisms annually. The company emphasizes technological innovation and has over a decade of experience in precision auto design, production, and quality management. They employ skilled personnel and utilize advanced testing equipment such as Japanese lMV vibration test benches, Mitutoyo measurers, and various environmental testers to ensure high-quality standards.

One-touch convenience for enhanced vehicle practicality and security.

Rapid response boosts logistics efficiency and reduces operational fatigue.

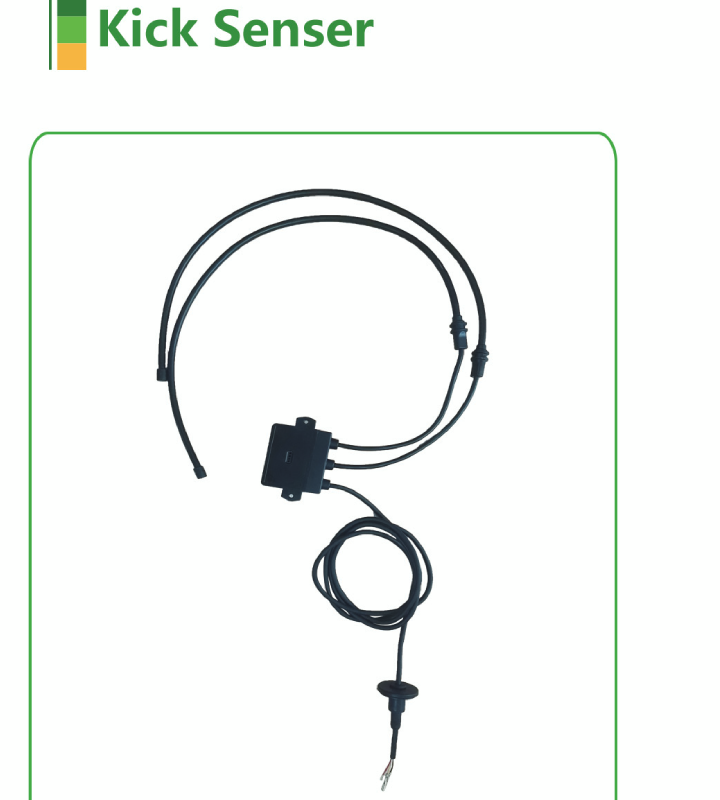

Intelligent sensing simplifies daily use with automatic opening and closing.

Voice control integrates innovative technology for a futuristic driving experience.

Yes, we provide API access and firmware customization to ensure compatibility with most vehicle management systems.

Our smart tailgates comply with ISO 26262, E-MARK, and CE standards, ensuring global market access.

Absolutely. We provide video tutorials, live webinars, and on-site training for B2B partners.

Lead times vary by quantity but typically range from 14 to 30 days. Express production is available for urgent orders.

Yes, we offer sample units at a reduced cost with a full refund upon bulk purchase confirmation.